Product portfolio

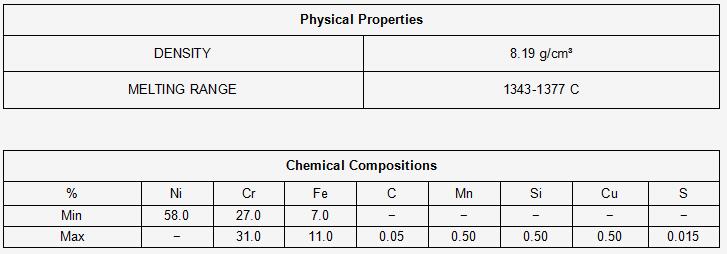

Inconel 690(UNS N06690) is a high-chromium-nickel alloy with excellent resistance to many corrosive aqueous media and high-temperature atmospheres. Its high alloy content gives it resistance to stress corrosion cracking in chloride-containing environments and moderate concentration of sodium hydroxide solutions. The high level of chromium imparts outstanding resistance to oxidizing environments and high-temperature oxidizing gases. It also has high strength, good metallurgical stability, and good fabrication characteristics.

Applications: Coal-gasification units, burners, and ducts for processing sulfuric acid; incinerators; furnaces for petrochemical processing; steam generator tubes; applications involving nitric acid or nitric /hydrofluoric acid solutions.

| Inconel 690 Tube & Pipe N06690 Nickel Alloy Seamless Pipe | |

| Outside Diameter | 10.3-426mm |

| Wall Thickness | 1.24-40.49mm |

| Length | Up to 25m |

| Standard | ASTM B163, ASTM B167, ASTM B407, ASTM B444, ASTM B622, ASTM B677, ASTM B829,etc. |

| Hastelloy Series | Hastelloy B(UNS N10001), Hastelloy B-2(UNS N10665), Hastelloy B-3(UNS N10675), Hastelloy C-4(UNS N06455), Hastelloy C-22(UNS N06022), Hastelloy C-276(UNS N10276), Hastelloy C-2000(UNS N06200), Hastelloy G-30(UNS N06030), Hastelloy G-35(UNS N06035). |

| Haynes Series | Haynes 230(UNS N06230), Haynes 556(UNS R30556). |

| Inconel Series | Inconel 600(UNS N06600), Inconel 601(UNS N06601), Inconel 617(UNS N06617), Inconel 625(UNS N06625), Inconel 690(UNS N06690), Inconel 718(UNS N07718). |

| Incoloy Series | Incoloy 020(UNS N08020), Incoloy 800(UNS N08800), Incoloy 800H(UNS N08810), Incoloy 800HT(UNS N08811), Incoloy 825(UNS N08825), Incoloy 925(UNS N09925). |

| Monel Series | Monel 400(UNS N04400). |

| Nickel Series | Nickel 200(UNS N02200), Nickel 201(UNS N02201). |

| High Temperature Alloys | GH2132,GH3030,GH3039,GH3128,GH3044,GH4080A. |

| Delivery Condition | Pickled&Annealed, Polished, Bright Annealed. |

| Technique | Seamless |

| Application | National defense, astronautics, transportation, equipment manufacture, shipping, petroleum, nuclear power industry, oil and gas industry, and chemical industry etc. |

| Marking | LOGO, Standard, Grade, Size, Heat Number. |

| Package | Woven bag, wooden cases, or as per customer's requirement. |

| Quality Requirement | Mill Test Certificate (EN 10204/3.1); Third Part Inspection is acceptable. |